Accelerating Robotic Surgery Innovation Through Early-Stage Partnerships

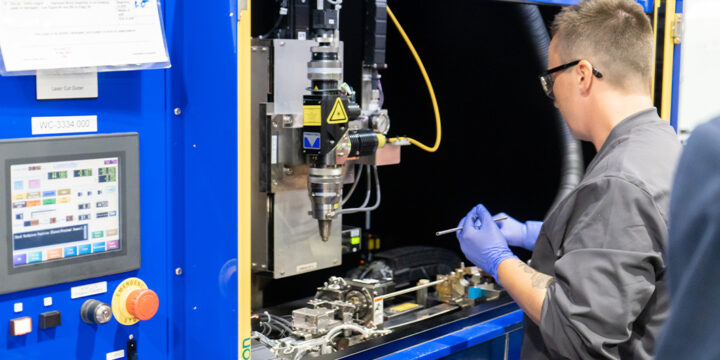

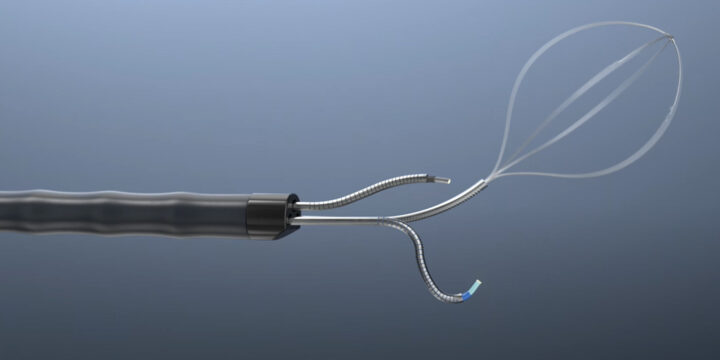

At DeviceTalks West 2024, NMT brought together a cross functional panel of experts in minimally invasive robotic surgery to discuss how early teamwork between academia, startups, and CDMOs fast-track the cutting-edge innovations that are revolutionizing robotic surgery of today. The Nissha Medical Technologies led panel was moderated by Tom Salemi and featured leaders from several of the leading robotic startups that are molding the current landscape of minimally invasive robotic surgery, including EndoQuest Robotics, EndoTheia, Inc. and Virtuoso Surgical.Panel Details:· Mike Springer, VP of Emerging Technologies at Nissha Medical Technologies· Dr. S. Duke Herrell, CEO of Virtuoso Surgical, CMO of EndoTheia, andCo-Founder of the Vanderbilt Institute in Surgery and Engineering· Scott Webster, COO of EndoTheia· Pejman Seyedi, Director of Advanced Visualization at EndoQuest The discussion highlighted the many challenges…