Micro Molding Revolution: Small Tech, Big Impact

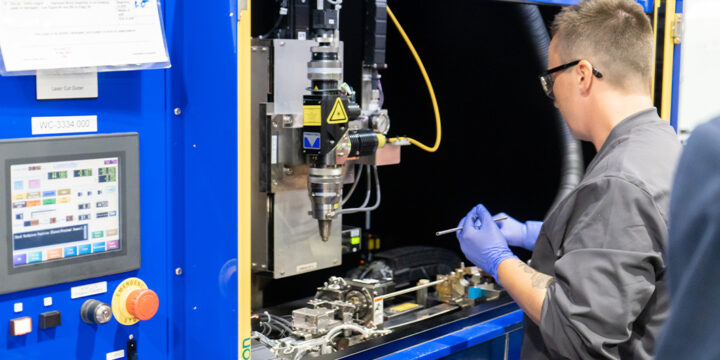

Our new partner, Isometric Micro Molding, is a leader in the fascinating world of miniaturization. But what exactly does that mean? Buckle up because we're about to shrink down to a whole new scale!The Mighty Micron: Measuring the MiniatureThe key to understanding miniaturization lies in a unit so small it's invisible to the nakedeye: the micron. One micron is a mere millionth of a meter (written as 10^-6 meters), or an even tinier 1/26,000th of an inch. It also goes by a few other names: micrometer, micrometre, or the symbol μm.A World Beyond SightThe micron is our ruler for the minuscule. Objects just one micron wide requires magnification to be seen The good ol' human eye can generally only distinguish particles around 40 microns in size.Putting It in PerspectiveImagine a human…